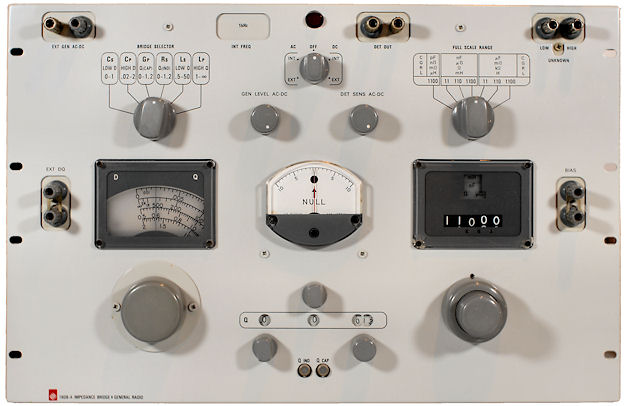

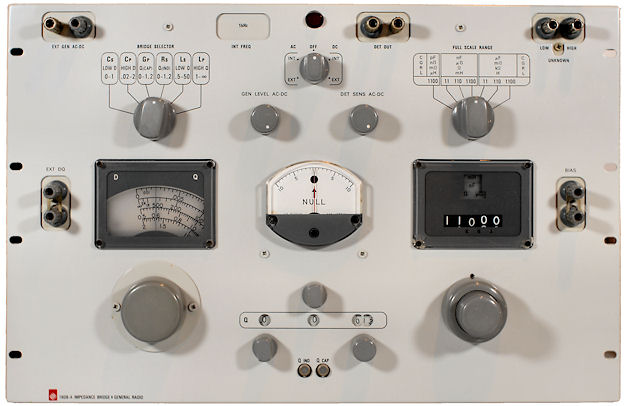

Today we refer to these as LCR bridges, but add conductance, rearrange the letters and you have CGRL. If I could have but a single bridge, the 1608-A would be the one. Actually, it's six bridges in one. It isn't as fast as the digital bridges. It isn't as accurate as the higher end digital bridges, or the standards lab bridges. It can't even measure dissipation factors as low as the much older 716-C. What it can do is make every major measurement in a single box, handle high voltages and a wide frequency range, plus provide better accuracy than almost any practical application needs. On paper it's 4X more accurate than the 1657 Digibridge, though in practice they come out about equal. It's particularly good for low value resistance measurements. Henry Hall, GR engineer and inventor of the Digibridge, says the later 0.05% versions of the 1608-A are probably the most accurate general purpose mechanical bridges ever made by GR, or by anyone else.

Internally, the 1608-A is built like a battleship. It achieves accuracy via precision mechanics. Today's economics (and modern digital methods) insure that such a monument to the mechanical engineering arts will never be seen again. This level of construction also insures that the 1608-A will be serviceable for as long as one desires to keep it going, or at least until the more complex things like the wire-wound pots and centade physically wear out.

The 1608-A was introduced in 1962 and was still listed in the 1978 GR catalog, the last one I have, giving it a run of at least 16 years. Early models were ±0.1%, later years were ±0.05%. They have either dark gray or light gray panels and a metal cabinet. Unlike most other GR instruments, the panel is a thin sheet metal overlay to the rougher finished heavy panel underneath. The price in 1970 was $1550 with a shipping weight of about 50 lbs.

The 1608-A can accept different slide-in RC modules for different oscillator and matched detector frequencies, but I've never seen other than the standard 1 kHz version that came with the bridge. It would be relatively easy to fabricate a new one based on the schematic and on the one that comes with the unit. On the other hand, it's just as easy to drive the external terminals with a signal generator unless a large amount of work at one special frequency is contemplated, and the use of the internal tuned detector is required. The internal detector is very good, better actually than it first appears because it has built in log response. Tuning the detector requires the never seen plug-in modules.

There are all manner of notes concerning special measurements and conditions in the manual, but one you should be aware of is that even though the frequency range is 20 to 20,000 Hz, the DQ dial has no overlap below 140 Hz when switching from Cs to Cp. I suspect this is nothing unique to the 1608-A. All it means is that low frequency capacitance measurements will require an extra resistance box if the device being tested has any significant losses. You can extend the Cs range for higher losses, or the Cp range for lower losses, insuring that just about any cap can be measured. I haven't experimented with similar measurements for inductors.

Make no mistake, measurements at the frequency extremes can be challenging with any bridge. If losses are high and impedances are low it may be difficult to find the balance point. Because the 1608-A operates from the mains, there will always be some residual 60 hz signal coupled in, which will beat against low frequency test signals. This becomes a problem near the lower limit of the bridges capability and the best solution is simply to unplug it and use an external signal generator and detector. The detector output of the 1608-A connects to the internal amplifier, not the bridge arms as in many other bridges. This gives you the advantage of a very high gain amplifier with flat frequency response and approximately log amplitude response, but the output is high impedance and you'll still need a tuned amplifier like the 1232-A to isolate the signal of interest. The manual gives a few charts and numbers suggesting that measurements can be made outside the 20 to 20 kHz range, but those measurements are so difficult and the accuracy degrades so quickly that I have to recommend staying well within the published range.

The 1608-A is at its best using the standard plug-in for 1 kHz. It's fast, accurate and easy. If you want to venture into more difficult measurements, every needed access point is there. Within its fequency limits, there are almost no measurements it can't be configured to make.

One interesting thing about the 1608-A is the construction of the reference capacitor (0.1488-0.1497 uF + pad). The specified accuracy of the bridge requires a very low temperature coefficient for the reference capacitor. Unlike the simple caps used in most other bridges, the reference cap of the 1608-A is a parallel combination of a mica and a polystyrene cap. They have opposite temperature coefficients and, when used in the correct ratio, give a total capacitance that's relatively immune to temperature changes. This is just one example of the level of design detail that you'll find throughout the 1608-A.

Details of the specifications varied over the production run, but these are the basics:

Before attempting to calibrate the 1608-A, any necessary service should be attended to. Right. The reality is that calibration usually shows up the parts that need service! I suggest using some tuner/switch cleaner on the exposed wafer switches, especially the range switch. Put some layers of paper towel under the switches to keep the tuner/switch cleaner where it belongs and sop up any extra. Any extra resistance in the range switch will show up as a calibration error. I spent way too much time fretting over a supposedly out of tolerance reference capacitor, only to find that the range switch was really the culprit. One squirt of Caig DeOxit took care of the problem.

Also check the power supplies and oscillator for correct amplitude and freedom from ripple. I recommend leaving the electrolytic capacitors alone unless proven bad, but an in-circuit test is still a must with these units. My 1608-A has suffered from several bad axial caps in both the oscillator and detector sections. Low voltage electrolytics like 50 uF @ 6 VDC seem to have a particularly bad history in all equipment, and the 1608-A is no exception. Given its age, all the electrolytics should be considered guilty until proven innocent. But, if they are innocent, don't muck up a perfectly good instrument due to some misguided notion about replacement "just for good measure". See my comments about "technician blight".

Note that GR bent the component leads over on the bottom, making removal difficult and risking the traces of the PCB. I'd strongly recommend that if an in-circuit measurements shows a dissipation factor greater than about 0.25, you should clip the offending cap out from the top, then carefully heat and drop the leads out from the bottom. The circuit board can be lifted up just enough to do the job if you unsolder the wires next to the front panel. Leave the wires on the side alone. There are four small spacers under the board, two short and two medium. Don't lose 'em or mix 'em up; the taller ones go on the shorter supports so the board is level in the case.

Several makers of high quality test equipment have suggested not unsoldering components at all; simply clip the leads near the body and solder the new part to the old leads. There is no shame in doing this and it's a far better thing than to do damage to what are now unobtainable circuit boards. Use your own best judgement.

There are a variety of gears and shafts that can benefit from sparse lubrication, but the key word is sparse. I use Break Free, available in any sporting goods shop. It's a synthetic oil with Teflon that doesn't gum up over time. Use a drop where shafts rotate and a light film on metal gears only. Switch detents can get a trace of Lubriplate or the Break Free. Avoid any greases from the auto parts stores as they invariably solidify over the years, creating more problems than they solve.

1608-A basic calibration is quite easy, and that's all that should normally be necessary. Though the manual gives some cryptic clues about padding various components to get everything in spec, any padding should have been taken care of at the factory, and should be unnecessary unless major components have been replaced. If the bridge won't balance at all, be sure the jumpers are in place between the BIAS and the EXT DQ terminals!

There is a potential problem I refer to as "technician blight". This can range from a minor disease to a terminal condition. The symptoms include wholesale replacement of components, lifted circuit board traces, mis-adjusted cams on the big GR pots, re-wiring, and units that seem impossible to calibrate. In general, GR equipment beats it specifications by a wide margin. Failure to do so usually indicates a subtle component problem, technician blight, or sometimes leakage due to contamination and old age. If you can't get the expected results, stop and think, study the schematics, and don't reach for a soldering iron until you're confident you understand the origin of the problem.

The basic calibration procedure consists of the following (this section is still under construction):

1. Measure an exact 10 kohm resistor on both the Rs bridge (11 kohm range) and the Gp bridge (110 umho range). The average of these two readings, neglecting the decimal position, should be 10000. If the average value is outside 9995 to 10005, adjust R16 on the small metal plate at the rear of the instrument, next to C17.

2. Check the fixed-bridge components by making the series of measurement in the table below. You will need a full set of accurate decade resistance standards from 1 ohm to 1 megohm, ideally better than 0.005%. Most of us don't have a full set of standards to that level of accuracy, but fortunately most bridges won't have issues with the fixed components!

| EXT STD | BRIDGE | RANGE | Ra RESISTOR | + means Ra is |

| 1 ohm | Rs | 1100 mohm | R7 | too small |

| 10 ohm | Rs | 11 ohm | R8* | too small |

| 100 ohm | Rs | 110 ohm | R9* | too small |

| 1 kohm | Rs | 1100 ohm | R10* | too small |

| 1 kohm | Gp | 1100 umhos | R14 | too large |

| 10 kohm | Gp | 110 umhos | R15 | too large |

| 100 kohm | Gp | 11 umhos | R11 | too large |

| 1 Mohm | Gp | 1100 nmhos | R13 | too large |

*Actually, the ratio arms for these ranges are the sum of several resistors, but if the previous measurement is correct, the indicated resistor is the component in error.

3. Measure any known capacitor near the top of a range. If the reading is off by more than 0.05%, correct by adjusting C17 (on the same small metal plate at the rear of the instrument).

4. The oscillator output control, R529, on the rear of the circuit board at the top of the instrument, should be set for no clipping as measured at anchor terminals 32 and 31, when the general level control if fully off (CCW).

5. Set mechanical adjustments (knob stops) per the manual. Check/set the DQ dial using a calculated capacitor/resistor combination. I use a 1000 pF silver-mica cap in series with a 7957.7 ohm resistor (trimpot) for a dissipation factor of 0.05. Set the Low D first, then the High D, as they use separate sections.

6. Fixed Q error on the Rs and Gp bridges is set with C3. Adjust C3 (just below the standard capacitor) to give a zero Q reading when a 1 kohm composition or film resistor is measured.

There are many more checks in the manual, but this simple list will tune up any bridge that doesn't suffer from circuit problems. For problems with the centade or detailed mechanical adjustments you'll need a manual. Replacing lamps requires considerable disassembly. The lamps are #327 type.

C. Hoffman

last edit October 24, 2011