Lots of other sites will tell you everything you need to know about the PAT-4. IMO, it doesn't require all that much to make it sound pretty good, and it also presents a good platform for additional mods if you're so inclined. That said, I think beyond a certain point the PAT-4 controls and hardware don't warrant a huge investment and if you're going for a state of the art preamp there are better places to start.

My goal was to take a typical garage-sale type unit and bring it up to a reasonable standard of listening without spending a fortune on boutique parts and without completely gutting it. You may wish to do more; you may wish to do less. Here are the things I did, and the reasoning behind them. I assume you have a schematic in front of you so you can follow along.

1) C1 becomes 22 uF, 25 volt minimum. I don't like having an electrolytic here, but this value is necessary to give the best RIAA response. It works in conjunction with the rest of the circuit response and if the value is changed the total response will peak or dip at the low end. Though it's counter-intuitive, making C1 smaller will result in an undesired peak, usually right in the record warp area. Making it larger can roll the LF response slightly- no, that's not a typo; if you don't believe me, simulate the circuit in LTSpice using an inverse RIAA network and mess with the values. The response effects are admittedly small so magnify the vertical scale of the response graph. You want a low loss capacitor here so no audio voltages appear across the cap; use a 25 volt part. Higher voltages have lower losses.

2) C3 becomes 470 uF, 25 volt minimum. This cap bypasses R4 and needs to be this large to keep its effects out of the audible region. A 25 volt part will give the desired low losses, though I admit to using a 6.3 volt because I had some decent axial caps with that rating. Do as I say, not as I do! Good axials are getting hard to find so use the better grade radials in most locations.

3) R7 becomes 60.4 kohms, 1/4W, 1% metal film. This improves the RIAA accuracy.

4) Add 820 pF (film, mica or C0G/NP0) cap in parallel with C6 (0.015 uF) on bottom of board. This improves the RIAA accuracy.

5) Delete C15. Odd I know, but the value of cap required to bypass a 33 ohm resistor (R18) without introducing effects in the audio band is too large to be practical. The cap simply increases the AC gain a bit, something not needed here, so get rid of it.

6) C13 becomes 2.2 uF film. This is the value necessary to give the flattest response to the output stage. Polypropylene would be the best choice here.

7) Change Q4 to a darlington device- just buy the upgrade kit from Update My Dynaco since you can't beat the price, or use something like MJE800 if you already have a suitable device. Use a small heat sink. I don't know if they originated the mod, but it's the most bang for the buck that one could ask for, decreasing the distortion of the output stage by about a factor of 10.

7a) Be sure R18 really is 33 ohms. This affects the feedback and bias of the output stage and can't vary much. Because it's part of the feedback system it should be a high quality 1% metal film resistor, not a metal oxide or ultra miniature resistor.

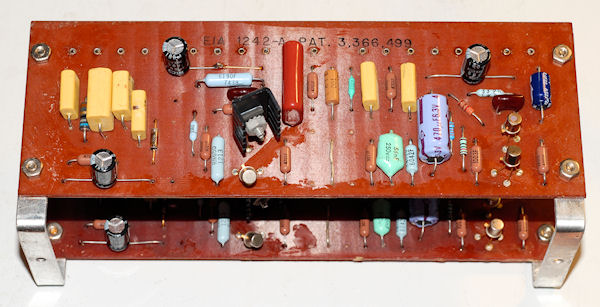

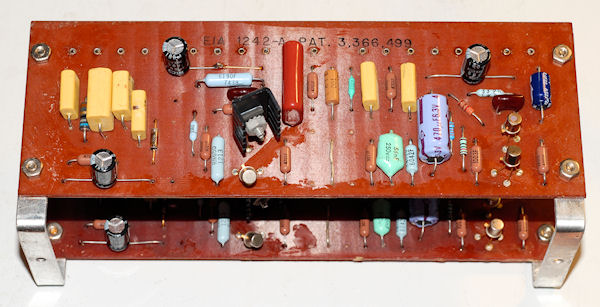

8) C16 and C21 become 100 uF 50 volt minimum. This helps the low frequency output drive a bit. Note that C16 is right next to R20, which runs quite warm. Offset C16 and extend one leg as shown in the photo at the top of the page. This will keep it cooler and increase its life, though it's not a huge issue.

9) OK, that takes care of alterations to the original circuit. Now the painful part. Given the age of your PAT-4, every carbon composition resistor and every aluminum electrolytic capacitor will be out of tolerance, if not completely bad. Replace every resistor in the unit with 1/4 watt, 1%, metal films. The usual parts from Yageo, Xicon or KOA are fine, or splurge on nice Dale/ Vishay RN55 or RN60 parts. R20 needs to be a 1 watt part. Don't forget to replace the 3.3 kohm resistor on the filter cap. It only needs to be 1/4 watt but larger is OK too. I used many RN60 sized resistors because I had them in stock but RN55 are fine in most places. Replace any other aluminum electrolytics not mentioned above.

10) Your main power supply filter cap may still be functional, but it's probably on its way out and IMO it was way too small to begin with. If measurements can confirm that all sections are still good and have low dissipation factor, you could keep it, but I'd suggest putting about 3300 uF in parallel with the middle section. A 50 volt part is OK there, but remember that the first filter runs just over 50, so be careful if you replace or add to that. There isn't much room around it anyway and a higher performance solution is to install a 2-output regulated supply, either from the company above, or a DIY version.

11) Some (all?) Dynaco RCA jacks are about 0.005" smaller in diameter than anything you'll find today. Thus, most RCA cables won't make good contact to ground. This can lead to no end of troubles with hum and noise. Use cables that can be adjusted (bent) to properly grip the RCA jacks, or consider replacing them. Note that most decent cable ends can't be bent that much without breaking them. You may have to make up cables with the more traditional 4-bladed tinned plugs.

12) Many people suggest disabling the tone controls but that's probably not necessary. If you have a scope, put a square wave through the preamp and install the tone control knobs such that they zero in the dead area where they're out of circuit. Check that everything works and the channels are matched and you're good to go.

C. Hoffman

last edit July 9, 2013