The Knight Bullet Burner is a 2-stage surface mixed glassworking torch. It's built entirely in the USA by Knight Manufacturing and sold by many dealers of glassworking equipment. It's also sold factory direct by Heathway, which is part of Knight.

The Bullet is a fine piece of engineering and there is actually very little that can be done to improve it. Still, there are a few tweaks that can be applied to make things work a bit more smoothly. The factory instructions are also a bit sparse, and a new user might benefit from what I hope are more detailed descriptions of what constitutes normal operation, and what doesn't.

Fuel/oxygen torches and gas systems are inherently dangerous in both obvious and non-obvious ways. You are entirely responsible for your own safety and must evaluate all information, such as this page, to determine its validity and applicability to your particular situation. This page may contain errors. I assume no liability for any loss or damage relating to the use of any information, correct or incorrect, on this web page. If these terms are not acceptable, use your browser's back button and leave this page now.

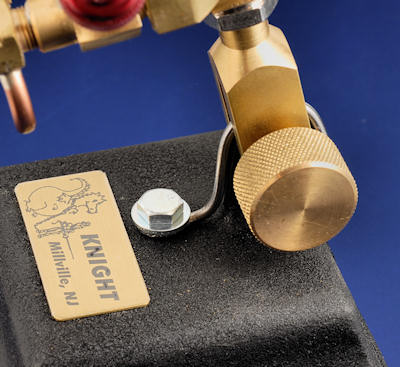

Surface mix torches, as the name indicates, mix fuel, typically propane or natural gas, and oxygen, outside the torch, on the surface of the burner face. Because of this you will sometimes hear that anti-flashback devices are not necessary. This is not correct. Though the fuel and oxygen mix outside the torch, they both have to pass through the same torch body. The construction of a surface mix torch is, of necessity, quite complex and there is a very real possibility of internal leaks in the system. Though the chance of a flashback is remote, that chance is not zero. Be sure to obtain and install anti-flashback devices, preferably at the torch end of the hoses. In the photo at the top of this page you can see two Hobart anti-flashback devices installed directly on the torch. The Bullet can be ordered with either hose barbs or standard welding torch "B" fittings. The "B" fittings make the installation of anti-flashback devices far more convienent.

The mark of a good repairperson is that he/she leaves no marks. The Bullet is nicely made, so try not to add any dings or gouges to it. Never use pliers on any nuts or parts, only good fixed or adjustable wrenches. Pad tools and fixtures with cardboard where necessary. Be sure to properly hold the opposite side of valves or plumbing so as not to bend or break anything, particularly when installing or removing hoses or anti-flashback devices. Unless you have a machine shop, capabilities far beyond the ordinary, and a direct line to the factory, make no attempt to open the torch body. The parts seal entirely via precision tolerances so there is nothing you can fix, and the chance of causing damage or leaks is quite high.

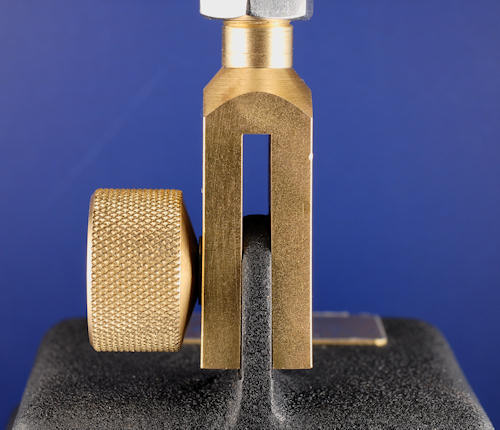

The Bullet has a split brass piece that clamps to a tab on the cast iron base when the locking knob is tightened. Nominally this works well, but can suffer from three annoying issues. First, the fit of the 1/4" x 20 tpi knob screw through the hole in the cast iron base is a bit loose. That results in an imprecise feel when changing the angle of the torch. It is also a partial contributor to an inability to solidly lock the torch; even with the knob quite tight, the torch may pivot a few degrees fore and aft. The second problem is that the brass fork is difficult to compress, such that only the strongest of fingers can solidly lock the torch. Finally, because of the high torque required to lock the torch, the 1/4" x 20 tpi socket head cap screw, which is press-fit into the brass knob, can slip and spin.

No doubt that makes things sound worse than they really are. There is probably some variation between torches and if you're happy with the way your adjustment works, you can skip this whole section!

The hinge system is generally quite functional, but it only takes a bit of work to make it vastly better. Let's address the knob first, since that has to be right for anything else to work correctly. If your knob has ever spun on the press-fit screw, it needs attention. If it hasn't, don't mess with it!

To fix it you'll need to remove the screw and this is best accomplished with a short piece of metal tube, a washer and a nut. If you can't find a suitable tube, a stack of large washers can be used instead. The hole in the tube or washers should be slightly larger than the head of the screw. Place the tube over the screw, against the back of the knob (pad it to avoid marks), install a smaller washer and a nut, then tighten the nut to pull the screw out of the knob. If it spun in the past, removal probably won't be too difficult. Now, go to the local auto parts store and get a small tube of Loctite #271 threadlocker. Clean the head of the screw and the hole in the knob. Apply a coating of #271 to the head of the screw and the wall of the hole in the knob. Press the two back together such that the screw head sticks out a small amount, about the thickness of a business card or less. You can probably use a drill press (unplugged) to keep things aligned while pressing the screw home or, lacking that, a small vise will suffice. Spin the pair by holding the screw in your fingers to be sure the knob doesn't wobble excessively, though a bit of wobble won't hurt anything. Let the #271 cure overnight. Be sure to wipe off any excess.

Because the screw is now slightly proud of the brass knob, the lower friction steel screw head will now lock the torch. If the brass area around the screw was contacting first, the friction would be higher, plus tightening the knob would tend to pull the screw out. The friction against the brass fork is still high, so find a thin steel washer with a 1/4" hole and install that so the screw head has something hard to work against instead of the soft brass. Put a little grease on the screw threads and under the screw head. The effort required to lock the torch should now be less, but we're not done yet.

With the knob removed, check the fit of the brass fork on the base. If it's loose, you'll have to work that much harder to compress it and lock the torch. With the base off, install a washer and another 1/4" x 20 tpi socket head cap screw (or a hex bolt). Using "mechanic-sized" tools, tighten the screw to compress the brass fork a bit beyond it's normal range. Release it. Check it against the base. Hopefully you can tighten it up a bit (I dare not use the word "bend", but that's what's needed) such that it just slips easily on the base as shown below. You can just barely see the flat washer installed under the knob. Locking should now be downright pleasant and we're on the home stretch of this mod.

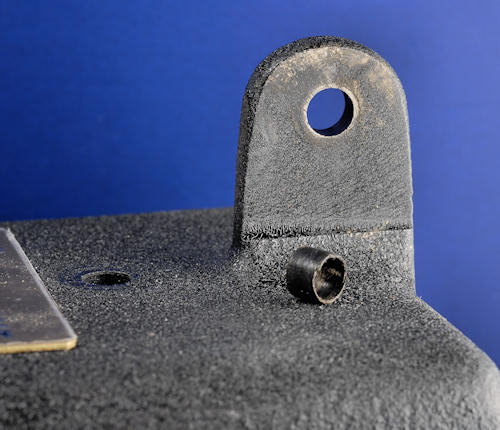

To gild the lily we now have to improve the fit of the screw in the cast iron base. The factory fit isn't bad, but it only takes a small amount of slop to give the torch an imprecise feel when changing the angle. Fixing this is easier said than done, because the fit isn't that loose and finding a small tube to take up the slop may prove impossible. The easy way out is to find someone with a small metal lathe and have them turn you a bushing. The hole in my base was 0.268" and the screw is 0.246". Thus, you want a Delrin bushing of 0.246" ID, 0.268" OD and 0.200" length. That's a wall thickness of only 0.011", so it's more like a piece of a plastic soda straw than anything. Put this in the hole in the base and then work the knob/screw through it. Torch motion and stability after locking should now be good enough to satisfy just about anybody.

Yes, the cast iron base is quite heavy, but you still need to fasten the torch securely to your workbench. No excuses. A myriad of very bad things could happen if the torch were pulled off the bench. Imagine a running torch spun around and the flame hitting you in the face and eyes. The damage would be done before you had time to react. Imagine the torch hitting the floor and breaking a gas line, which would then ignite in a good size fireball. Hopefully I've made the picture sufficiently clear.

You can fasten the Bullet to the bench in a variety of ways. Some people use C-clamps because they don't want to put a hole in the bench. It works, but it's ugly. If you use clamps, check 'em frequently. The Bullet base has a single hole for a 1/4" bolt. You can use a lag bolt that screws right into the wood of a bench, but I prefer a more elegant approach.

Any hardware or home store will sell 1/4" x 20 tpi T-nuts. Drill a hole in the bench, then draw or pound a T-nut into the bottom of the hole under the bench. Now you have strong metal threads so you can fasten the Bullet with a good machine bolt.

For thick benches, or benches where the underside is inaccessible, there are also brass thread inserts that can be installed from the top. You may have to go to a woodworking shop for these. I prefer them to the T-nuts, but you have to drill the right size hole and install accurately for full strength. Install them from the top using a hex head bolt to drive them in. A 1/4" x 20 brass insert and a rusty T-nut are shown below. The T-nut has had the back cut off for clearance. With proper threads it's now easy to remove and reinstall the torch whenever and as many times as you want.

There are some comments on the web concerning broken Bullet bases. Apparently the the drilled mounting tab can break off if the torch is subjected to impact. Being cast iron, this isn't too surprising since the stuff is somewhat brittle. I suspect it would take a good whack to the torch, but the danger is that it might crack, and then some subsequent minor bump could unexpectedly finish the job. Having the torch securely mounted to the bench makes breakage more likely, but not mounting it is not an option. If it breaks all the very bad things described in the previous section could then occur. What's worse is that without the stabilizing base the torch body could be pulled off the table by the hoses.

I simply don't know if this issue is real or not. I didn't see any first person reports of broken bases, but it seems like a possible failure mode. It might be more of a concern in a commercial enterprise where things get banged around and handled more roughly. At any rate, it concerned me enough to design a bit of extra protection. The following should restrain the torch if the mounting tab breaks, but understand that it's never been tested as I've never broken a base.

Get some steel rod about 1/8" in diameter. Bend a loop in one end to fit a 1/4" bolt. You can bend it around a spare bolt in a bench vise. Make a 90 degree bend shortly after the loop. Now, screw it to the base and bend it around the top of the tab as shown. Cut it off and file the end smooth. The fit doesn't have to be perfect.

There's quite a bit of room in the fork, so the rod shouldn't interfere with the motion of the torch. Now if the tab breaks the mounting fork will remain trapped by the rod, which is ultimately fastened to the bench by the mounting screw. The torch should remain on the bench, pointed in a safe direction.

The Bullet instruction sheet (downloadable from Heathway) is good as far as it goes, but there are a couple things that could be added. Should you intend to work fused quartz, Heathway informed me that the Bullet is perfectly happy using hydrogen. Warning- there are many other safety issues you need to know about before using hydrogen! I should also add that I've worked small fused quartz projects with the Bullet, using just propane and oxygen, and had no complaints whatsoever.

The most confusing statement in the instruction sheet concerns the caution about torches making a loud bang when the oxygen is suddenly cut off. As far as I can tell, once the lines are purged, a properly operating Bullet won't make a loud bang under any condition. It doesn't matter what order you turn the fuel or oxygen on or off. It doesn't matter if you do it suddenly or slowly. The torch should never pop or bang. Ever. At most, it may make a brief and slight fizzle noise when the oxygen is first turned on.

If your Bullet pops or bangs under any condition, it almost certainly has an internal leak. You need to contact Heathway for repair arrangements.

To be sure, you can do a leak check. The results aren't infallible as they may indicate a leak where none exists, depending on your ability to seal the front ports. However, if the test indicates no leak, then you almost certainly have no leak. What you need to do is seal the ports on the face of the torch. This can be done with some vinyl electrical tape and thumb pressure. Then, you need to apply about 2 or 3 PSI of air or oxygen pressure to one of the inlets. Put a piece of clear hose on the other inlet and drop it in a glass of water. Open the inner stage torch valves and look for bubbles in the glass while keeping thumb pressure on the tape. The idea is that there should be no connection between the fuel and oxygen sides of the torch within the torch body, so there should be no bubbles. Shut off the inner stage and open the fuel and oxygen valves for the outer stage. Look for bubbles. Now, open all valves and look for bubbles in the glass. If you have no bubbles you almost certainly have no leaks. If you get bubbles and no amount of fiddling with the tape and thumb pressure eliminates them, you should suspect an internal leak.

It's easiest to pressurize the oxygen side of the torch because it's already hooked up. Unfortunately it's a bit harder to seal the oxygen ports on the burner face than the smaller fuel ports. If you have trouble you can try pressurizing the fuel side with oxygen if you have hose barbs or hose barb adapters. In any case you may have to experiment with thumb pressure or even a piece of soft rubber to get the ports sealed. You can also do the test with a low pressure gauge instead of the water glass, if you have a suitable one. The three tests will tell you if there's a leak on the inner stage the outer stage, or a leak between the two. My guess is this test will work with most surface mix torches, as long as you can get a good seal on the ports.

CAUTION: Purge the lines after the leak test to flush the oxygen out of the fuel gas side and vice versa!

The instructions don't say anything about normal operating temperatures of the torch body, nor do they talk about proper candle length. This is probably because the torch is well designed and not overly fussy about operating conditions. My experience is that with only the inner stage running, the torch body and most of the stainless steel nosepiece will stay quite cool. The torch doesn't seem to have any problem with short candle lengths, though I don't like to run less than 1/4". Remember that the flow of oxygen contributes greatly to cooling so the torch will likely run hotter with an oxygen starved reducing flame than the more useful oxidizing flame.

It would be unusual to run the outer stage at a low level and 1/2" or greater candles would be the norm. The stainless steel nosepiece and torch body will heat up under those conditions, though the brass body and first inch of the nosepiece should never be uncomfortable to touch. It's normal for the last inch (front) of the nosepiece to pick up some heat discoloration. To make it look like new again use a bit of Barkeepers Friend cleanser (most supermarkets carry this) and water on a piece of paper towel; don't get any in or on the front burner face.