Blank diameter is critical to quality knurling. The wrong blank diameter can cause the knurl(s) to double track, giving a pattern finer than the knurl was designed to produce, one that's generally unsatisfactory. To make your knurling come out properly with no double tracking you need to select the blank diameter of your stock to match the pitch of the knurl. This is very similar to having two gears of the same diametrical pitch that fit together. Every time you add a tooth the diameter increases by a discrete amount. There are no in-between diameters that work correctly. The same is true of knurls and the blank to be knurled, though fortunately knurls do tolerate a certain amount of error before problems occur.

There is a modern standard for knurls that makes the blank diameter easy to determine, but not all knurls are made to that standard. Standardized knurls work correctly on stock diameters in 1/32" increments or some similar number, depending on pitch. The problem is that we often have knurls of unknown origin and specification. I bought my Eagle Rock scissors knurling tool many years ago and had no idea what the pitch of the knurls was. I also collect used and antique knurls. Knurling was a hit or miss proposition; sometimes it came out great and other times it would double or triple track no matter what I did.

Machinery's Handbook has knurling formulas, though somewhat confusing directions on how to apply them. Information is also available on other web sites and from manufacturers, but you still need to start with information about your knurls. The whole thing is a headache without straightforward instructions. Here's a simple method to determine what you've got and how to select the correct blank diameter.

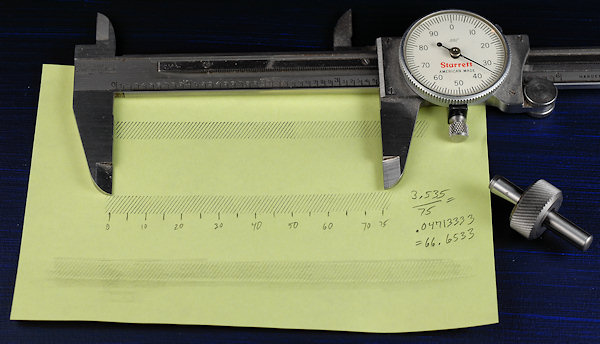

Grab one of your knurls and a pin to fit it. Clean the knurl. Ink the knurl on a stamp pad and roll it down a piece of paper. If you don't have a stamp pad, ink up a piece of paper with that tube of Hi-Spot Blue you forgot you had and use that. Lacking that, just make an impression on the paper by pressing down a little harder. Shade it with a pencil to make it more visible.

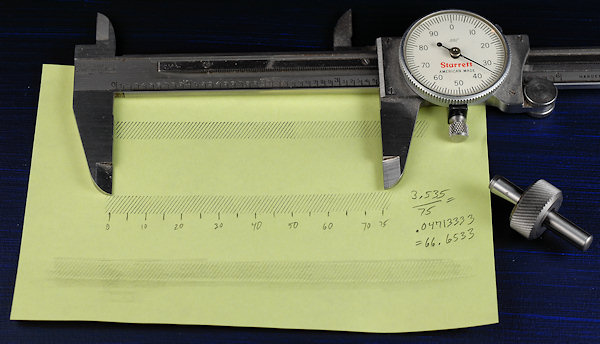

Now, count a good number of lines, maybe 50-100. It helps to mark every fifth one with a pencil and count the groups. Measure the distance with verniers. In my case I counted 75 lines and measured 3.535 inches. Divide to get the spacing: 3.535 / 75 = 0.0471" Make this measurement and record the number for each knurl you own.

This is actually the circular pitch (CP) of the knurl. The diametrical pitch (DP) of the knurl is π/CP, but we don't really care about that. What we do care about is the inverse of that number, CP/π, because the diameter of the blank you intend to knurl must be some multiple of it. In my case 0.04713 / 3.1416 = 0.015"

Let's say I want to knurl a piece of 5/8" stock (0.625"). 0.625 / 0.015 = 41.666 That remainder of .666 is the mark of the devil and suggests that the knurl will give problems. We don't want a remainder, at least not a significant one. Since we know knurling will increase the OD of the part, and we know that the multiplier is about 41, we can just use 41. 41 * 0.015 = 0.615 By turning the blank down to 0.615 we know there's an excellent chance of the knurl tracking correctly and giving a clean pattern.

With coarse knurls you can also measure the knurl OD and count the teeth to arrive at the same numbers, but the above method uses more revolutions and is somewhat easier to do, especially for fine knurls. Concave knurls can be printed on the white stem of a cotton bud, the edge of a piece of white mat board or a piece of paper wrapped around a small metal rod.

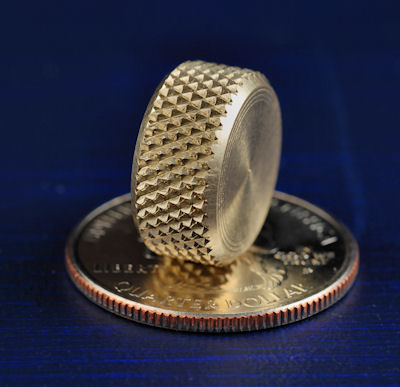

You'll notice that we're working with numbers relating to the surface of the knurl and not worrying about the depth of the pattern. It's my feeling that once the knurl makes in initial clean impression, it can't help but follow that impression to full depth. Thus, I tend to revolve the spindle manually with mild pressure to establish that clean impression, and then increase the pressure to go to full depth. It's possible that if you go to full depth immediately, the numbers will have to be adjusted slightly, but try this first.

To summarize, "fingerprint" the knurl and measure the circular pitch. Use stock with a circumference that's a multiple of the circular pitch, or stock with a diameter of the circular pitch over π.

The usual knurling advice still applies: Make no more rotations than necessary or the knurl will pick up flakes of metal. Use plenty of oil to flush away debris and prevent the knurls from seizing on the pins. Sometimes an air blast helps keep debris off the surface.

Almost too easy!