Many people create HSS lathe tools using nothing more than a bench grinder and get perfectly acceptable, if not downright excellent, results. For most normal sized projects with moderate tolerances that may be all you'll ever need. As tolerances get tighter, or improved surface finishes are required for decreasing part sizes, better tools are needed. You can't shave tenths and simultaneously get a great finish with a dull tool.

My goal is to show you some practical techniques that can quickly be applied to improve the edge quality of your tools. The techniques are neither authoritative or backed up with extensive research. They are simply things I've picked up over a good number of years building close tolerance assemblies, scientific instruments, plus reading and watching how other machinists, some having far more knowledge and experience than I do, make things. With some thought you may well build on, and improve, the ideas covered here.

It should be mentioned that my focus is exclusively on generating extremely sharp edges and you can't blindly apply that type of tooling to every situation. Razor sharp edges are exactly what you don't want in most high speed production situations with stainless steel and other alloys. This tooling isn't for roughing or for cleaning the scale off mill finish steel. These edges won't have the durability needed for volume production.

So when do you need these tools?

Tool angles are well covered in many places, from Southbend's How to Run a Lathe, to the web, to Machinery's Handbook, so I won't spend time on finding the perfect rake angle for cutting 6061 aluminum. Information on how to achieve maximum sharpness of cutting edges is a lot harder to come by, and that's the real topic of this page. I have to add that we all seem to have absorbed a lot of erroneous folklore concerning sharpness, starting back when a well meaning friend or relative showed us how to sharpen that first pocket knife. A conversation about carbide tooling is also in order, as its an option with many strengths and pitfalls, especially for the home machinist.

The exact details of what happens when we "cut" metal is also outside the scope of this page, but the reader is encouraged to do some additional research. Start with the search term "mechanics of metal cutting". If you look at the cutting action of the typical lathe tool, you'll see that the actual cutting takes place along a line, and usually a very short one at that. The line may be bent and have a radius, but as long as sufficient relief is present, what happens 25 thou away from that line is irrelevant to the process. Thus, when we talk about tool angles, it's the angle right at the cutting edge that's important. Everything I present below is an attempt to control the geometry in that tiny area of the tool where cutting takes place.

It only takes a single pass on a stone, or a millisecond at the grinder, at the wrong angle, to destroy the geometry of the cutting edge. There is no way to sharpen freehand and get a quality edge. You have to use some kind of guide system. I can already hear the Crusty Old Machinists calling me an idiot and making all sorts of claims about how they can shave with their freehand sharpened tools. The fact is, they can. Why? They cheat. They use a guide system, whether they realize it or not.

The neophyte often rocks his tool all over the grinding wheel due to lack of skill and practice. The Crusty Old Machinist may do the same thing, but only to increase the metal removal rate when roughing things out. After that, he usually keeps the entire face of the tool in intimate contact with the wheel. You'll see only a hollow ground area with a single radius on his tools. As the he brings the tool to the wheel, and especially when he removes it, he's careful not to grind on the cutting edge. Thus, even though he may not realize it, the cutting edge is being protected by the inherent guide system of the curved tool face riding against the curved grinding wheel. It's not perfect, but it's a technique you should master because it leads to the next step of refinement.

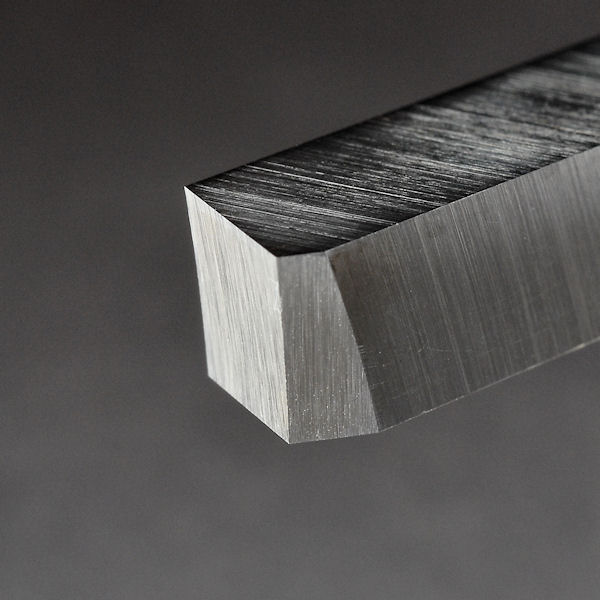

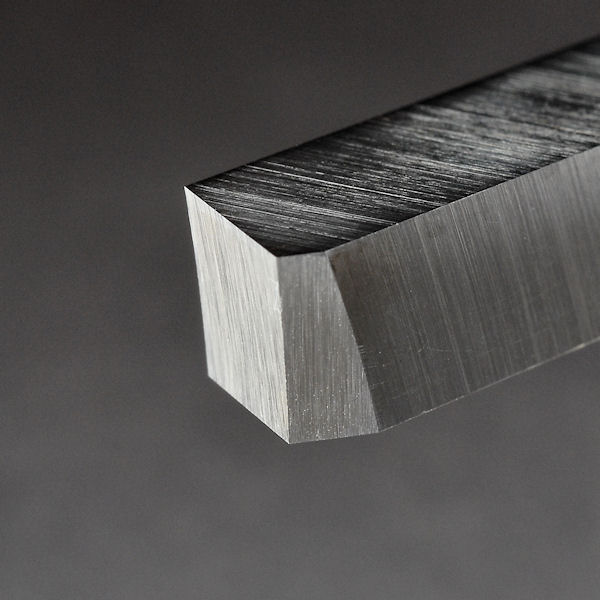

Here's about what a tool should look like coming off the grinder. You would also want some top rake and maybe a chip breaker for most applications, but note the clean and slightly curved faces. This was ground on an ordinary 8" off-hand grinder using no rests at all. The main (side) cutting edge is the one facing you, though the tool will also cut very well the other way, if the depth of cut (DOC) is small.

If you've done the rough grind correctly, several things will have been accomplished. First, the cutting edge will be quite sharp, usable for many things as is. Second there will be considerable relief angle under the edge because the angle is greater than the average angle of the curved grind. Third, and very important, there will be a well defined edge on the lower side of the tool. That edge is the simple guide system that will prevent damage as the cutting edge is stoned to perfection.

As long as that lower edge of the tool remains in contact with the stone, you can avoid the errant stroke that creates a new facet on the cutting edge. Lift off that lower edge and in a single swipe across the stone you create a small facet at the wrong angle that requires a huge amount of corrective stoning to remove. The lower edge also determines the relief angle that will be produced, so pay attention during grinding to be sure the overall shape is correct.

Think in terms of facets, just like those cut on a diamond. When they catch the light they should look like perfect planes, with no rounding near the edges. Some people sharpen tools using silicon carbide paper. Though it can be effective to a point, it invariably rounds the edges, blunting the tool and causing rubbing just below the actual cutting edge. In profile this looks just like a worn tool. Even though the overall relief angle might be 8°, it's the almost microscopic angle at the edge that matters. Understand that at some level of magnification the edge will always look dull, and the relief angle non-existent, so a certain amount of judgement is required to match the edge to the application. When the cutting edge rubs you need extra pressure to make it cut. A correctly formed edge will cut nearly on contact, dusting off as much or as little material as you need.

Suitable abrasive tools for refining the edge include hard Arkansas stones, synthetic oil stones, the harder Japanese water stones (rarely used for metal cutting tools) and the various plastic lapping films. Do not use pressure sensitive adhesive (PSA) backed lapping films as the compliance of the adhesive will cause rounding at the tool edge. You can keep plain films from sliding by putting a drop of water on the back. Use the films with a heavy sheet of glass or a surface plate. Lapping films are available with almost every known abrasive. Diamond is suitable for carbide and works acceptably with HSS, in spite of general advice not to use diamond with ferrous metals. Aluminum oxide is less expensive and works well for HSS. 12 micron is a good general purpose grade. 9 micron is probably as fine as is really needed. For coarser work the commonly available plated diamond hones are quite good and very durable. Be sure to get a solid one, as the ones with perforations tend to catch the tool tip.

Here's that same tool above, hand stoned with a small medium Arkansas, and then a fine black one, using both edges as the guide system. By always keeping both edges in contact with the stone, rounding of the cutting edge is avoided. A smooth radius has also been stoned in between the faces. Remember, the quality of that radius will determine how good a surface finish you can get. Sometimes people will keep increasing the radius, trying to improve the surface finish, when they really just need a high quality cutting edge on the radius they've already got. A large radius will increase the tendency to chatter. A small radius, like this one, needs to be fed very slowly, but also won't deflect small stock. The relief angle under the cutting edge is 6° (aka the end relief angle) and the front edge angles away the tip at 15° (aka the end cutting edge angle).

The top surface of the tool is often ignored, but it's as important as the faces. If the top surface is rough, no amount of stoning on the other faces will give a clean cutting edge. The grinding marks on the top will extend through the cutting edge, degrading the surface finish of the work being turned. They will also reduce the durability of the cutting edge. If you grind rake into the top surface, follow the same procedure as above and stone it smooth. If you leave the top of the tool flat, it's still good practice to stone it. I speed things up by placing a thin piece of tape on the rear of the tool. This gives a tiny amount of negative rake, but allows the tip to be quickly improved without having to remove a lot of metal.

Modern shop practice tends towards zero or even negative rake tools, but these are rarely suited to the home shop. Positive rake will make your tools free cutting, reducing deflection and power requirements. With steel you can use 10-20 degrees, but never try to use a tool ground for steel on brass; it will grab and possibly rip the stock from the chuck or damage the lathe itself. Consult the various references for the correct angles to use with different materials. Sharp tools with the correct angles can make all the difference between a job going smoothly or being nothing but trouble.

Grinding lines should always be perpendicular to the cutting edge. If the lines are parallel to the edge, the edge will be more fragile. As an example, drill sharpening fixtures are usually shown set up on the horizontal centerline of the wheel, making the grinding lines parallel to the cutting edge. Ideally they should be raised so the drill tip touches the wheel on the vertical centerline so the grinding lines are perpendicular to the cutting edge. Or, you can raise the grinder and work on the lower part of the wheel. If the nature of the setup puts the grinding lines parallel to the cutting edge, stoning is even more important to refine the edge into clean facets and prevent the cutting edge from failing across a large horizontal area.

Very sharp edges are not inherently durable, but the smoother and more defect-free you can make them, the longer they'll last.

OK, I wasn't going to talk about tool angles, but the shear tool deserves special mention. I've only seen it described in a few machining texts, and the description was usually incomprehensible. I never understood the tool until it was properly described in an on-line forum. It has but a single specialized purpose, that of finishing materials that tend to tear. If you can't get a good finish on some difficult grade of steel, this is the tool to try. Be aware that it has many limitations. As shown, it will only cut from right to left, and the depth of cut is rarely more than 0.001". It's hard to get close to a shoulder without careful grinding and a low contact point. Both the spindle speed and feed rate are generally kept quite slow. Slow power feed is thus preferred, especially if the part is long. Use oil.

The tool nose is ground at a slight angle to provide clearance, just a few degrees. The cutting edge is usually 30-40 degrees off vertical. Stone until smooth and sharp. As you can see below, the vertical position of the tool is not critical, in fact when one spot becomes dull, just raise or lower the tool a bit. Operating correctly, this tool will produce a chip that looks almost exactly like steel wool. Under the right conditions the shear tool can give a finish so smooth it could be mistaken for ground.

The factory supplied rests on most grinders are nearly useless. With a bit of searching on the net, you can find plans for much improved rests and tool holders. I also recommend buying a copy of Tool and Cutter Sharpening by Harold Hall, Workshop Practice Series #38, which includes much sound advice, along with plans for many easy to build grinding fixtures.

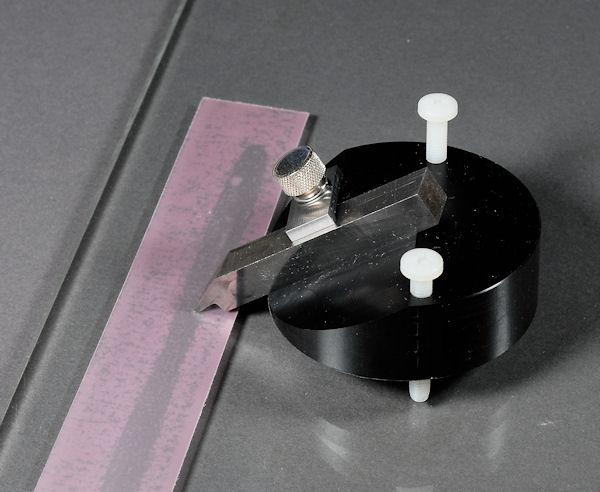

Still, most of what's available only addresses the grinding part of the process and my focus is on getting a better edge than grinding alone is likely to give. I mentioned pocket knives earlier and nothing puts a better edge on a knife blade than the original Lansky Sharpening System. They use a guide, clamped to the blade, that prevents accidently stoning the edge, even briefly, at the wrong angle. Each stone has a long rod extending from the back that rides in the guide. The same principle can be applied to almost any edge you want to touch up, including end mills and dovetail cutters. You can make up your own stones by glueing them to a bar, or using lapping film (this is where the PSA is useful), but I just use the Lansky stones right from the standard set. Here's the basic idea for touching up an end mill, though one would want things tied down a bit better than sitting on the studio seamless. Yes, I know this is about lathe tools; use some imagination and apply the technique to whatever edge you need to deal with.

The methods above will suffice for almost all typical turning needs using HSS and cast alloy tool blanks. The angles can be held to sufficient accuracy by eye and experience. This is not the case for threading. As a bare minimum you should use a "fishtail" gage to check the included angle and squareness of the tool, but that still leaves you a long ways from what can be achieved with very little additional effort.

Once you've roughed out the tool on the grinder, you need a fixture to perfect the angles. I made the fixture shown here from a scrap cutoff of Delrin. I had made a rectangular one some time back but it grew legs, so they must be desirable. The exact shape and dimensions aren't important, though you should try to keep the two feet and the tool tip near the points of an equalateral triangle. The only strict requirement is that the tool bit can be fastened in very close a 30° angle and that all angles can be fine tuned using two adjustable feet. The fixture is a kinematic design; it has three contact points making it completely stable in use. The angles can be changed slightly, but you'd need a different fixture for Acme or other threads with significantly different angles.

PDF file for thread honing fixture

You can make a nice angle template out of aluminum roofing flashing. Just scribe it and cut it on a paper cutter (not a rotary cutter). Here's the fixture being set up for the main 30° angle. If you want to work from a different side of the tool, or the fixture itself, the template can certainly be cut to reflect that preference.

Next we go to the back of the tool to set the relief angle. It will be necessary to go back and forth a couple times because the adjustments interact.

If you look closely you can see the perfect facet at the tip created by the ultra-fine black Arkansas stone. The nearby edge of the tool catches the light, but it's still rough ground and didn't hit the stone.

You can also use the fixture on glass or a surface plate with lapping film. This is pressure sensitive aluminum oxide film, and the adhesive backing rounds the facet slightly, resulting in a slightly less sharp and less free cutting tip. Try to get plain lapping film.

Now, flip the tool over in the fixture, readjust, and tune up the other side. You may want to remove excess material that doesn't need to be lapped as described shortly, so the lapping operation goes swiftly. With a properly ground tool, lapping shouldn't be any more than a ten minute job.

OK, tell me again why we need this level of control over the edges? For a thread to function properly, the flanks of the screw need to contact the flanks of the nut. If the angles are off, the contact area will be a narrow high pressure line near the ID or OD of the thread. The lubricant won't be able to support the pressure and you'll get metal to metal contact, possibly galling and certainly higher friction than would otherwise be the case. If you're making a 1/4 x 20 bolt, it probably doesn't matter. If you're making an adjustment screw for a laser mirror mount, it certainly does matter.

For conventional HSS lathe tools the hollow grinding technique described above works well. For threading tools that get lapped using a fixture you can save a huge amount of work by removing unnecessary material at the grinding wheel. You should be lapping the minimum amount of material necessary to the function of the tool. If it only takes .050" of material to support the cutting edge, don't waste time trying to lap more than that. If the maximum thread depth you ever cut is .025", grind the tool so you don't have to lap .5" every time you sharpen it. This is even more of a time saver with carbide.

Carbide is a wonderful thing for many jobs. Very little HSS is used commercially anymore. You'll hear that carbide isn't as suitable for the home shop as HSS, but I don't fully subscribe to that view. The problem is that commercial carbide inserts are designed for production use on completely different machines than most HSMs own. They're typically not very sharp, may have negative rake and may have coatings that only function at high cutting rates that produce high temperatures. There exist sharp uncoated inserts for aluminum, and these should be fine even on a small light machine as is usually found in the home shop. In general I find inserts are an expensive and unnecessary complication for the HSM.

Brazed carbide tooling ranges from poorly made imports, to the very fine Micro 100 tooling. Other than those high end tools, few brazed tools perform their best right out of the box, and you can't fix this using only a green carbide wheel. More likely you'll make things worse. If you want carbide to perform like HSS, you have to create sharp edges like HSS, and that requires diamond abrasives. For threading tools, follow the procedures above, but use a green wheel followed by diamond lapping films. Easy, problem solved. For other lathe tools the best solution is a slow speed diamond wheel grinder like the Accu-Finish, or a diy version of the same thing. Lacking that, the diamond lapping films will get you where you want to go, slowly, but once you've used a purpose-built carbide grinder with a proper adjustable sliding table and diamond wheels, you'll be too spoiled to consider anything else.

I might add that, lest you think I'm over the deep end, the Accu-Finish people provide a smooth ceramic grinding disk, plus a bottle of fine diamond fluid to charge it. The result is a mirror finish on carbide, and a razor-like edge. There's no question that most jobs can be done using much more casual techniques, but when you need perfection it's good to know how to get it.

Stay Sharp!